TM 9-2350-222-34-1

FINAL DRIVE REPAIR (Sheet 25 of 30)

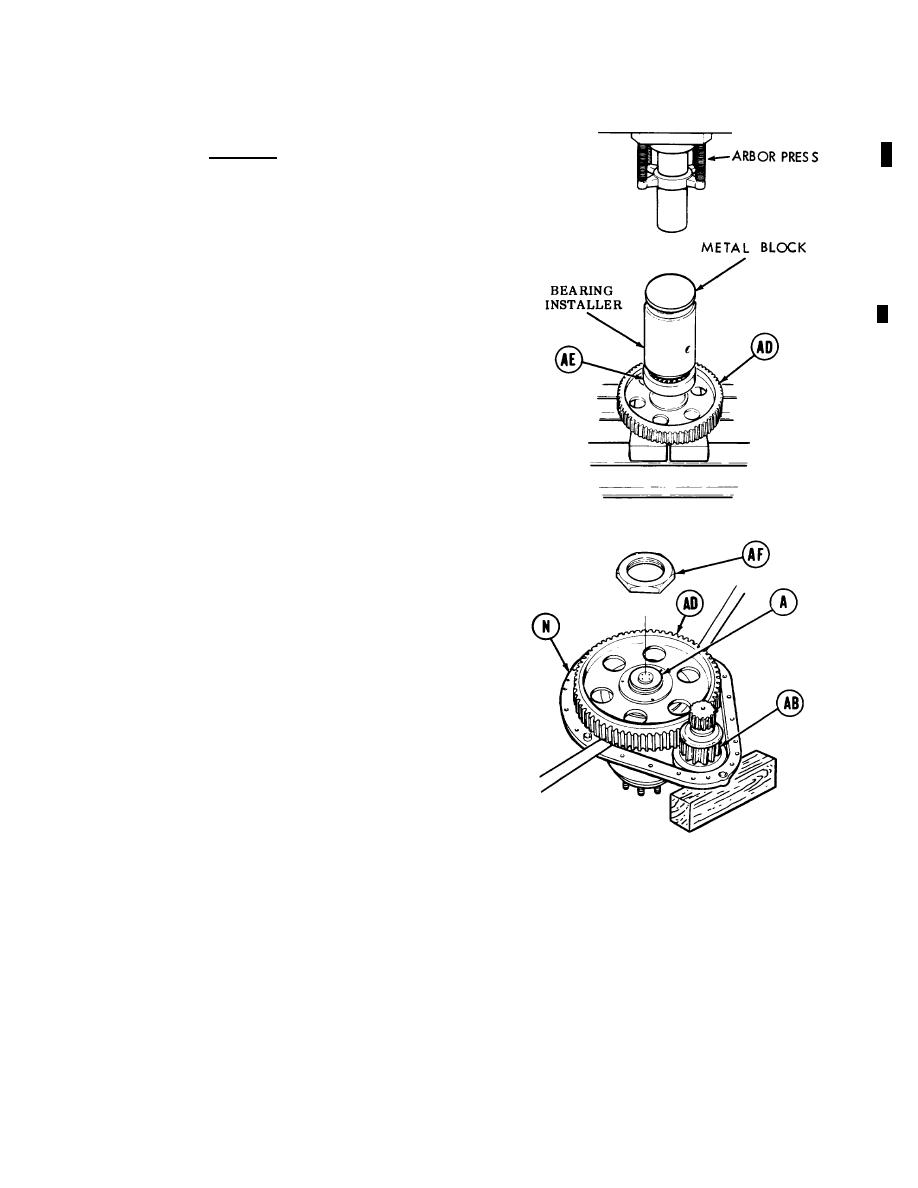

CAUTION

Place supports under center of drive

gear (AD) to prevent damage during

pressing operation.

53.

Position metal blockton bearing installer. Using

arbor press, apply pressure to plate until bearing

(AE) is fully seated on drive gear (AD).

54.

Position drive gear (AD) in carrier (N).

55.

Using two pry bars positioned directly across

from each other, carefully pry drive gear (AD) up

and mesh drive gear (AD) with pinion gear (AB).

56.

Carefully lower drive gear (AD) and pinion gear

(AB) into carrier (N) until seated.

57.

Apply oil to threads of output shaft (A) and nut

(AF).

58.

Install self-locking nut (AF) onto output shaft (A).

Using special box wrench, tighten nut (AF).

Go on to Sheet 26

Change 5 7-25