Preparation for Special Shipping Width

The machine should be prepared for special shipping

width when it is necessary to reduce the width of the

machine to 2591 mm (102 in).

NOTE: The following procedure is for reducing the

shipping width of the machine by collapsing the blade.

There may be other steps required to fully prepare the

machine for shipping. Refer to “Operation Section,

Transportation Information” in the Operator’s Manual.

1. Drive the machine onto the transport vehicle, park

the machine in position for shipping, and apply the

parking brake.

NOTE: It is possible to perform this procedure while

the machine is not on the transport trailer, and then

drive the machine onto the transport trailer after the

blade has been collapsed. However, care must be

taken not to operate the blade angle function while the

blade is collapsed, to avoid damaging the angle

cylinders.

2. Angle the blade fully in the desired direction, and

put the blade in position 25 mm (1.0 in) off the deck

of the transport vehicle.

NOTE: The blade must be off the deck of the

transport machine to allow manual positioning of the

blade after the angle cylinders are disconnected.

3. Stop the engine. Refer to “Operation Section,

Machine Parking, Engine Stopping,” in the

Operator’s Manual.

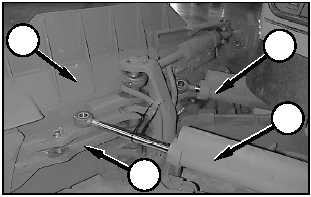

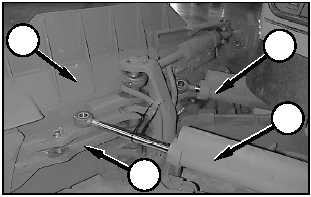

4. Remove bolt (2), pin retainer (3), and pin (1) from

retracted angle cylinder (4) and extended angle

cylinder (5). Put the pins, bolts and retainers in a

location where they will not be lost during transport.

NOTE: It may be necessary to drive pin (1) in the right

angle cylinder down in order to remove the pin.

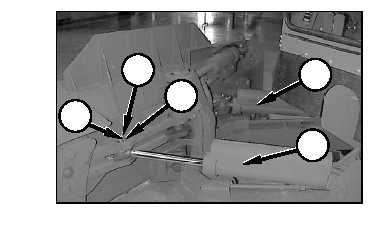

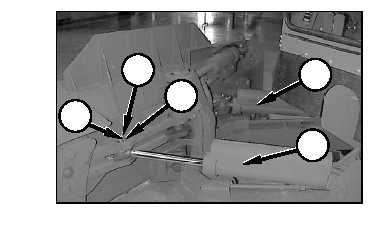

5. Slide angle cylinders (4) and (5) with the spacers out

of single tree (7). Collect the spacers, and place

them in a location where they will not get lost

during transport.

6. Rotate blade (6) by hand until the blade stops

against the singletree.

7. Slowly move the blade control lever into the down

position to allow the blade to rest on the transport

vehicle deck.

NOTE: It is not necessary to start the machine to

lower the blade. The blade will lower under its own

weight when the blade control valve is moved into

LOWER. If the start switch is in the ON position, the

machine must be in EARTHMOVING mode to lower

the blade.

8. Secure the blade in the fully angled position to

ensure that it does not move during transport.

9. Secure angle cylinders (4) and (5) to keep the rod

eyes from moving during transport. Make sure that

the chrome portion of the cylinders will not come

into contact with any hard surfaces during

transport.

NOTICE

Do not wrap metal chains or other metallic retainers

around the chrome portion of the angle cylinders.

Damage to the chrome surfaces will cause the

cylinders to leak and allow dirt into the hydraulic

system.

10. Cover the exposed chrome portion of the cylinders

in a suitable material to protect the chrome from

damage during shipment.

6

4

7

5

1

2

3

4

5

E-7

Appendix E

Unit Level Transportation Information

TM5-2430-200-10