NOTE: The following steps are for returning the blade

to normal service after the blade has been prepared

for special shipping width.

11. Remove all of the tie-down fasteners and

protective coverings from the blade and the angle

cylinders.

12. Start the engine. Refer to “Operation Section,

Engine Starting” in the Operator’s Manual.

13. Raise the blade until it is approximately 25 mm (1

in) above the transport vehicle deck.

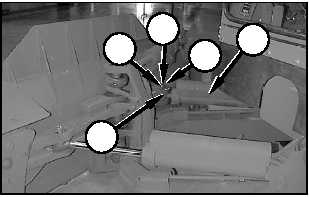

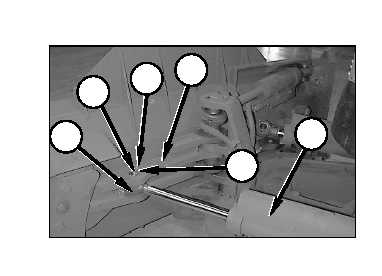

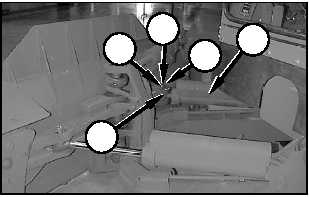

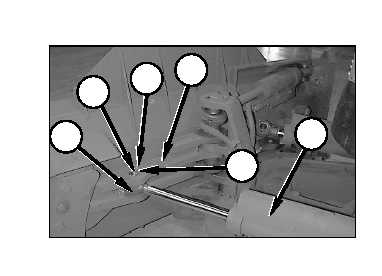

14. Move rod eye (8), of extended angle cylinder (5)

into position in singletree (7). Rotate the blade by

hand to achieve correct alignment between the

holes in the singletree and the hole in the rod eye.

15. Install one spacer above and below the rod eye to

remove the vertical gap between the rod eye and

the singletree.

16. Install pin (1), retainer (3), and bolt (2).

17. Lower the blade to the ground, and apply slight

downward pressure to the blade to keep it from

rotating.

NOTE: The machine must be in EARTHMOVING

mode to lower the blade when the start switch is in

the ON position.

18. Put rod eye (9) of retracted angle cylinder (4) into

position in singletree (7).

19. Operate the blade angle function to extend or

retract the rod eye of retracted angle cylinder (4)

until the rod eye is aligned with the hole for the pin

in singletree (7).

20. Install one spacer above and below the rod eye to

remove the vertical gap between the rod eye and

the singletree.

21. Install pin (1), retainer (3) and bolt (2).

22. The blade is now ready for normal operation.

NOTE: Be sure grease the angle cylinder pins before

using the machine to do work.

1

2

3

4

9

1

2

3

7

8

5

E-8

Appendix E

Unit Level Transportation Information

TM5-2430-200-10