TM 9-2350-222-20-1-5

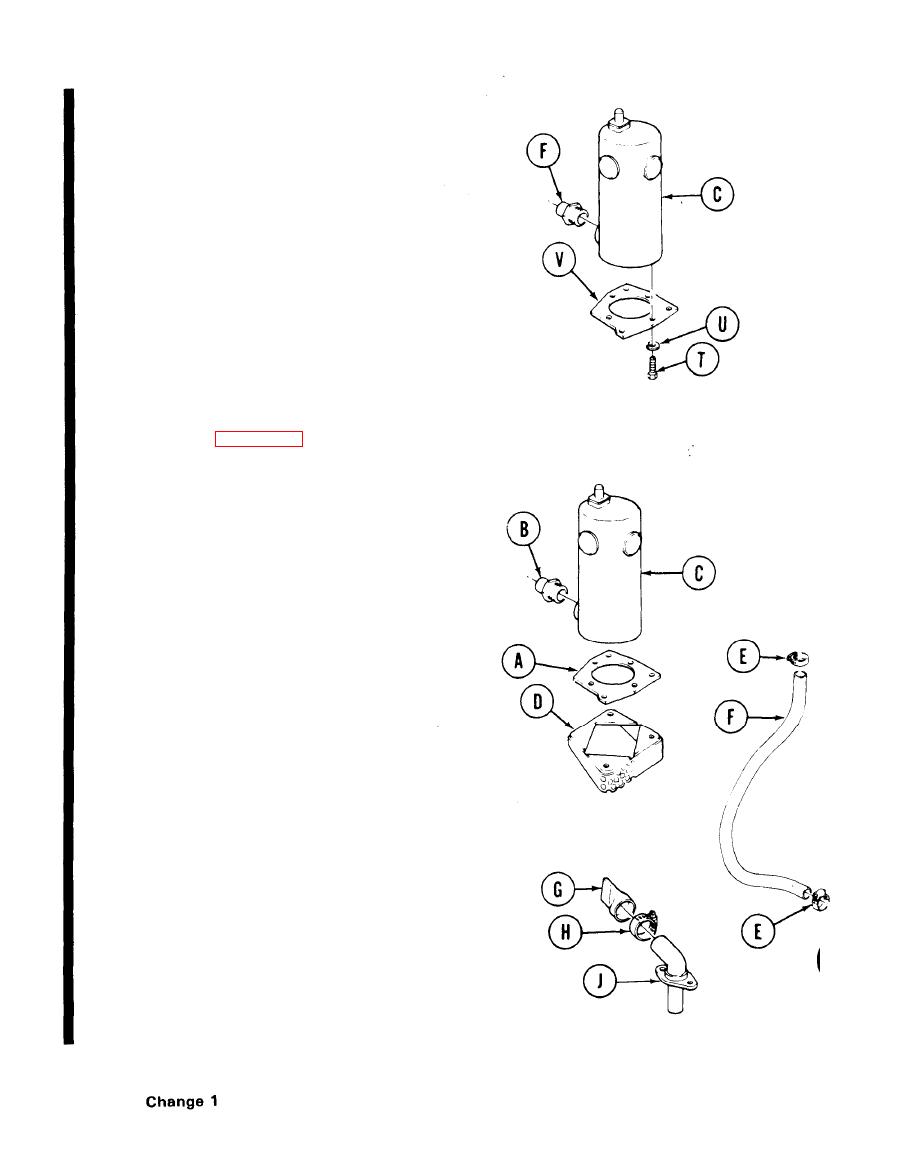

BILGE PUMP REPLACEMENT (Sheet 3 of 6)

19. Using 2 inch wrench, remove bilge pump

adapter (F) from bilge pump assembly (C).

20. Using 7/16 inch wrench, remove four

screws (T) and lockwashers (U) from

mounting plate (V) and bilge pump assem-

bly (C). Remove plate (V). Throw lock-

washers away.

CLEANING AND INSPECTION:

NOTE

Before inspection, clean all

parts thoroughly with clean

rags and dry cleaning solvent

(Item 54, Appendix D).

1.

Check bilge pump mounting plate (A) for

cracks, corrosion, or excessive wear. Re-

place if required.

2.

Check threads on adapter (B) for corrosion,

wear, and damaged threads. Replace if

required.

3.

Check bilge pump (C) for corrosion, cracks,

and wear. Replace if required.

4.

Check screen (D) for corrosion, excessive

dirt, or damage. Replace if required.

5.

Check hose clamps (E) for corrosion and

wear. Check screw and nut threads for

damage. Replace if required.

6.

Check hose (F) for breaks, cracks, or wear.

Replace if required. Reposition hose (F)

after inspection.

7.

Check valve (G) for cracks, corrosion, and

wear. Replace if required.

8.

Check clamp (H) for corrosion and wear.

Check screw and nut threads for damage.

Replace if required.

9.

Check elbow (J) for cracks, breaks,

corrosion, and wear. Replace if required.

Go on to Sheet 4

TA253847