TM 9-2350-222-34-1

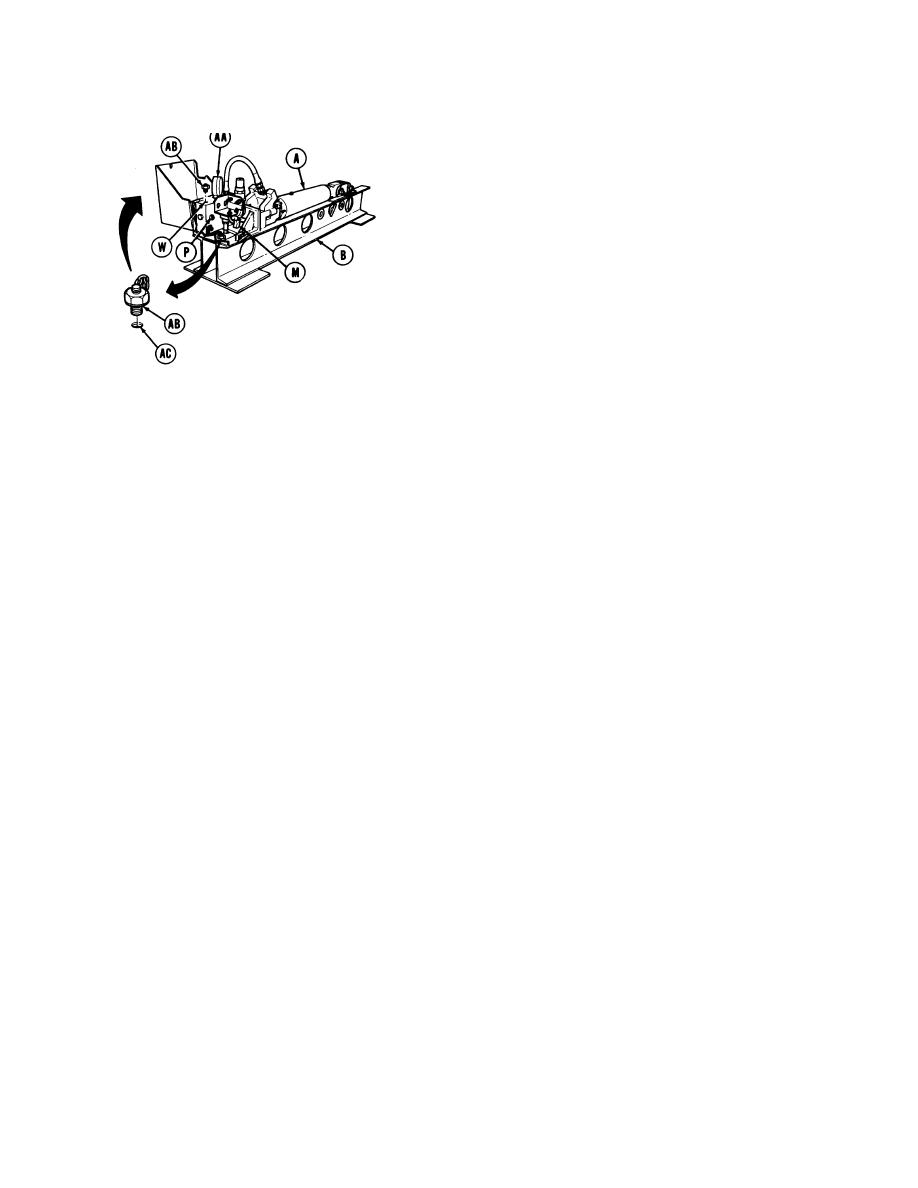

TRACK ADJUSTING LINK REPAIR (Sheet 10 of 13)

15. Using 7/8 inch wrench, remove test fixture plug

(AB) from storage hole (AC) in test fixture frame

and install plug (AB) in manifold block hole (W).

16. Turn needle valve handle (M) fully clockwise to

close.

17. Using grease gun, pump grease into manifold

grease fitting (P) until gage (AA) indicates 2500

psi.

18. Inspect track adjusting link (A) for grease leaks.

If any leaks are found, turn needle valve handle

(M) counterclockwise to release pressure,

remove adjusting link (A) from test fixture (B),

and tag link (A) unserviceable.

19. Turn needle valve handle (M) slowly counterclockwise until gage (AA) indicates 700 psi, then turn needle valve (M)

clockwise to close.

20. Wait 5 minutes, then check gage (AA). If gage (AA) indicates drop of more than 100 psi, repeat steps 17, 18, 19,

and 20. If gage (AA) still indicates drop of more than 100 psi, turn needle valve handle (M) counterclockwise to

release pressure, remove adjusting link (A) from fixture (B), and tag link (A) unserviceable.

Go on to Sheet 11

TA248775

Change 2 9-38