TM 9-2350-222-34-1

TRACK ADJUSTING LINK REPAIR (Sheet 9 of 13)

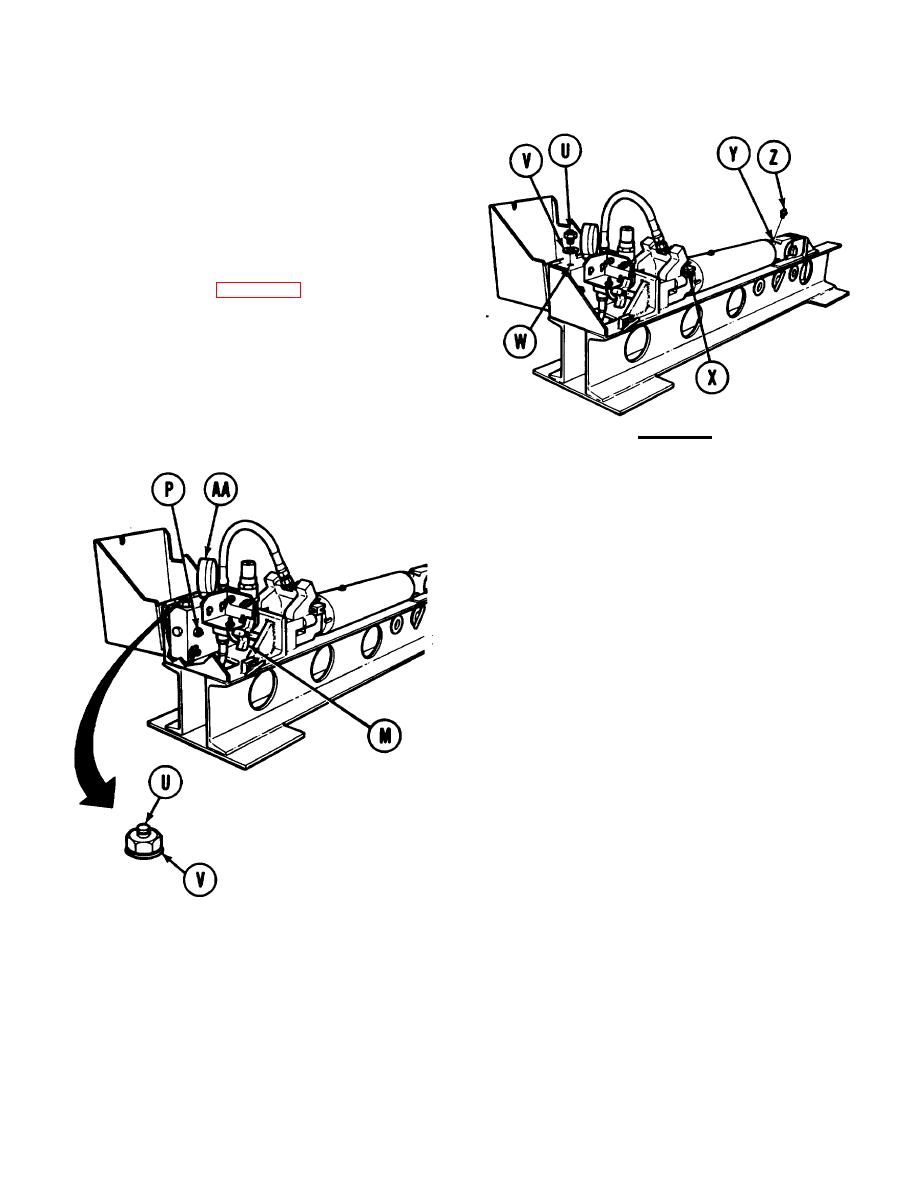

NOTE

Relief valve (U) used in next step was

removed from track adjusting link

yoke at disassembly.

11. Install new packing (V) on relief valve assembly

(U). Coat threads of valve assembly (U) with

grease (Item 14, Appendix B).

12. Using 15/16 inch socket and torque wrench,

install valve assembly (U) into manifold block

hole (W) and tighten to 40-60 lb-ft (54-81 Nm).

13. Using grease gun, pump grease into fitting (X)

until grease comes out pipe plug hole (Y) on end

of adjusting link. Using 3/8 inch wrench, install

WARNING

and tighten pipe plug (Z).

Wear goggles and cover relief valve

with a rag to prevent grease from

getting in eyes. Relief valve opens at

2150-2250 psi and blows a fine spray

of grease.

14. Watch gage (AA) and pump grease into manifold

grease fitting (P) until relief valve (U) opens

between 2150 and 2250 psi. If valve (U) opens

between 2150 and 2250 psi, turn needle valve

handle (M) counterclockwise to release

pressure. Remove valve (U) and packing (V),

throw packing (V) away, and go to step 15. If

relief valve (U) does not open between 2150 and

2250 psi, turn needle valve handle (M)

counterclockwise to relieve pressure. Remove

valve (U) and packing (V) and throw away valve

(U) and packing (V). Install new valve (U) and

new packing (V) (steps 11 and 12) and repeat

this step.

Go on to Sheet 10

TA248774

Change 2 9-37