TM 9-2350-222-34-1

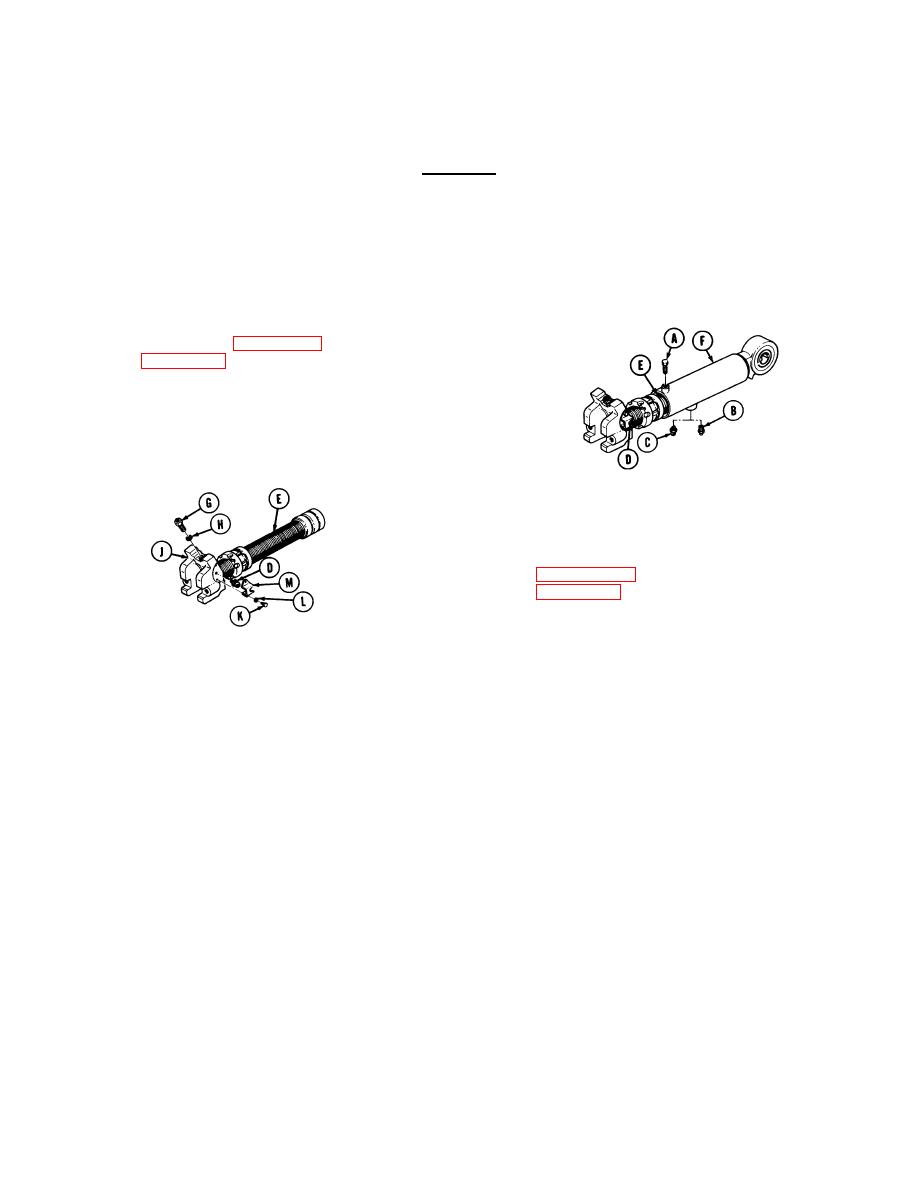

TRACK ADJUSTING LINK REPAIR (Sheet 2 of 13)

DISASSEMBLY:

WARNING

Dry .cleaning solvent P-D-80 s toxic and flammable. Wear protective goggles and glove and use

only in a well-ventilated area. Avoid contact with skin, eyes, and clothes and don't breathe vapors.

Do not use near open flame or excessive heat. The flash point for Type #1 Dry Cleaning solvent is

100F (38C) and for Type #2 Is 138F (50C). If you become dizzy while using cleaning solvent,

get fresh air immediately and get medical aid. If contact with eyes is made, wash your eyes with

water and get medical aid immediately.

1. Clean dirt and rust from track adjusting link with

solvent (Item 12, Appendix B) and rag (Item

22.1, Appendix B).

2. Using 3/4 inch socket, remove lockscrew (A).

3. Using 7/16 inch socket, remove safety relief

valve (B). Using 7/16 inch socket, install grease

fitting (C) in safety relief valve hole.

4. Using grease gun, pump grease into fitting (D)

until shaft assembly (E) comes out of cylinder

(F). Wipe excess grease from shaft assembly

(E) and cylinder (F) using rags (Item 22.1,

5. Using 15/16 inch socket, remove relief valve (G)

and packing (H) from shaft assembly yoke (J).

Throw packing (H) away.

6. Using 7/16 inch socket, remove two screws (K)

and lockwashers (L) securing support (M) to

yoke (J). Remove support (M) from yoke (J).

Throw lockwashers (L) away.

7. Using 7/16 inch socket, remove grease fitting (D)

from yoke (J). Throw fitting (D) away.

Go on to Sheet 3

TA248767

Change 2 9-30