TM 9-2350-222-20-1-5

HYDRAULIC PUMP DISCHARGE TUBE ASSEMBLY REPLACEMENT (Sheet 1 of 4)

PROCEDURE INDEX

PAGE

PROCEDURE

Removal

Cleaning and Inspection

Installation

Ratchet with 1/2 in. drive

TOOLS: 1-5/8 in. open end wrench

9/16 in. socket with 1/2 in. drive

1-1 1/16 in. open end wrench

10 in. extension with 1/2 in. drive

1-1/2 in. open end wrench

6 in. flat-tip screwdriver

9/16 in. combination box and

7/16 in. socket with 1/2 in. drive

open end wrench

SUPPLIES: Rags (Item 65, Appendix D)

Dry cleaning solvent (Item 54, Appendix D)

Engine oil (Item 43, Appendix D)

Drip pan

Lockwasher (MS35338-27) (4 required)

Lockwasher (MS35338-25) (2 required)

TM 9-2350-222-10

REFERENCES:

LO 9-2350-222-12

PERSONNEL: Two

PRELIMINARY PROCEDURES: Traverse turret placing boom over right front fender

(TM 9-2350-222-10)

Open turret platform access cover (TM 9-2350-222-10)

Disconnect battery ground straps (page 10-283)

Dump driver's seat (TM 9-2350-222-10)

Open front hull drain valve (TM 9-2350-222-10)

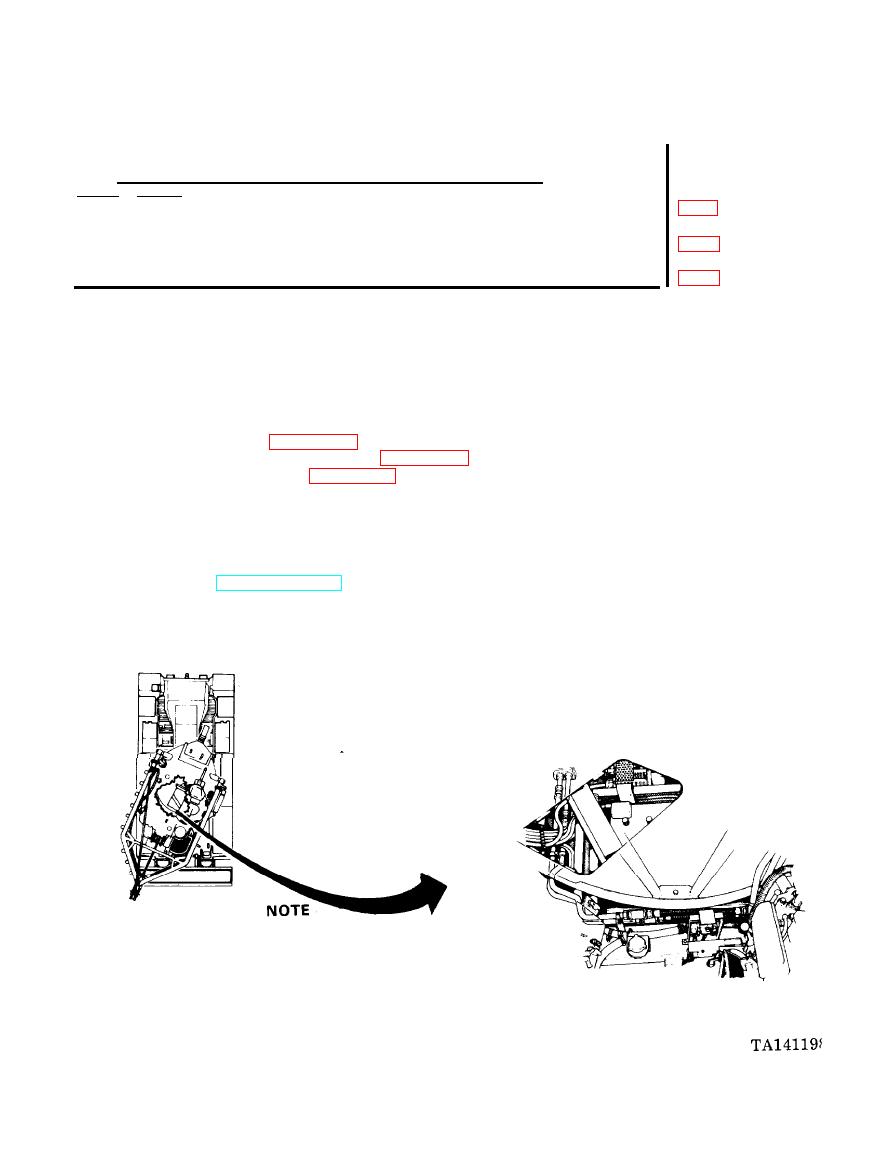

Traverse turret as needed during tube assembly removal and

installation. Removal and installation procedures for front and

rear hydraulic pump discharge lines are the same.

It is

necessary to remove front filter line to gain access to valve on

rear filter line.

Go on to Sheet 2