TM 9-2350-222-20-1-4

ROADWHEEL ARM REPAIR (Sheet 5 of 9)

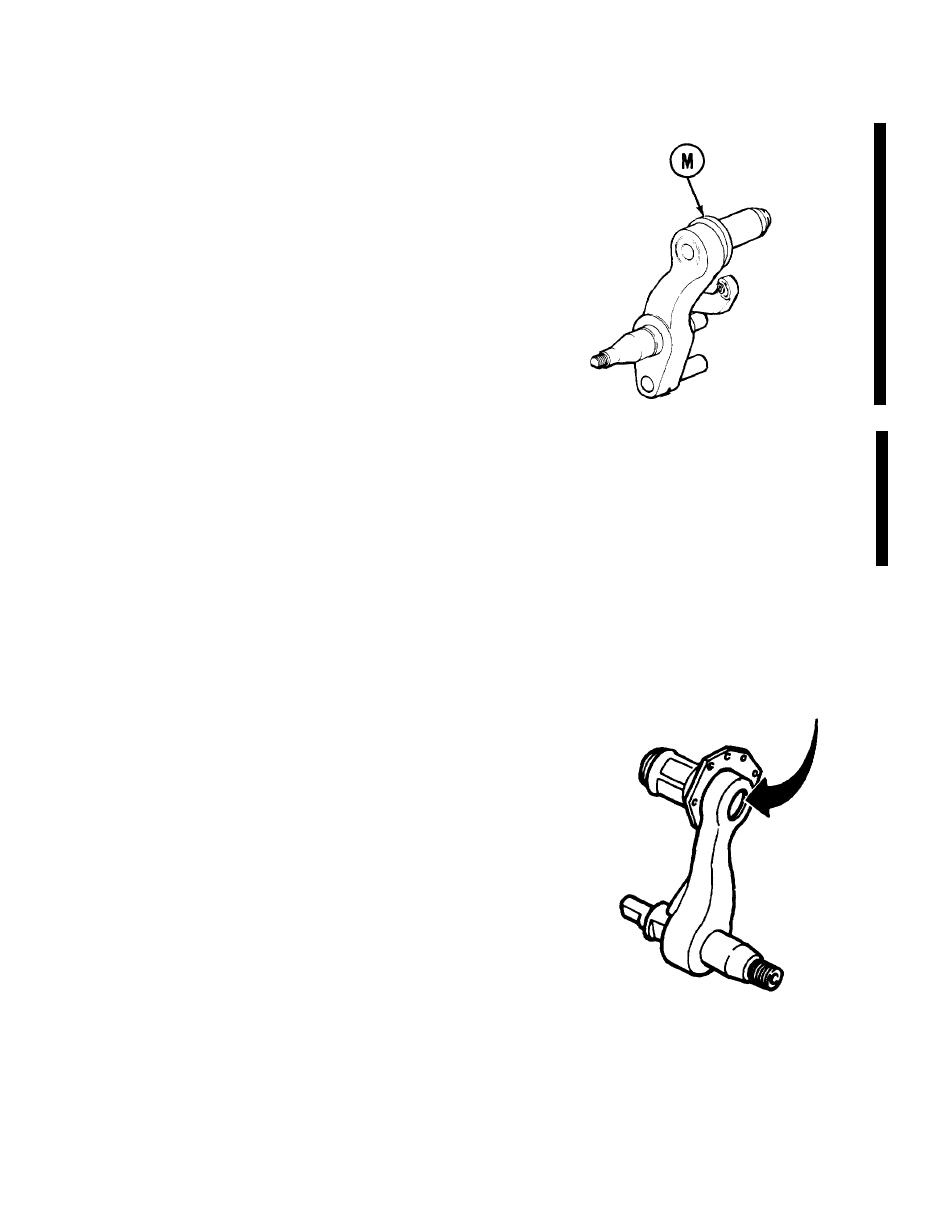

Inspect deflector (M) for bending, cracking, or

12.

wear. If damaged, carefully remove deflector (M)

by tapping around its outer face with hammer

and chisel.

CLEANING AND INSPECTION:

WARNING

Dry cleaning solvent P-D-680 is toxic and flammable, To avoid injury, wear protective goggles and

gloves and use in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and do not

breathe vapors. Do not use near open fire or excessive heat. The flash point for Type I dry cleaning

solvent is 100oF (38oC), and for Type 11 is 140F (60oC). If you become dizzy while using dry Cleaning

solvent, get fresh air immediately and get medical aid. If contact with eyes is made, wash your eyes

with water and get medical aid immediately.

1.

Using dry cleaning solvent, clean all parts, especially bearings.

Check arm for cracks. If arm is cracked or bad, turn in to support maintenance and replace

2.

with new arm.

Inspect both upper and lower spindles of arm,

3.

INTERNAL SPLINES

especially threads.

4.

Check internal splines of arm for broken,

cracked, or deformed splines. If bad,

replace arm.

5.

Using file, smooth out any rust spots, pits,

or other damaged places on arm. Do not file

spindle.

Inspect bearings for missing needle rollers

6.

and scuffs or scratches, especially on

inner races.

7.

Replace defective parts as required.

Go on to Sheet 6

14-13

Change 5