TM5-2430-200-10

85

Operation Section

Towing Information

Towing Information

Personal injury or death could result when towing

a disabled machine incorrectly.

Be sure all necessary repairs and adjustments

have been made before a machine that has been towed

to a service area is put back into operation.

Follow the recommendations below to properly

perform the towing procedure.

NOTICE

The winch cable is rated at 195 712 N (44,000 Ib). This

cable can be used for self-recovery but cannot be used

to tow another DEUCE.

NOTICE

This

machine

is

equipped

with

internally,

spring-

applied parking brakes. The parking brakes must be

hydraulically released before the machine can be

towed. Also, the final drives must be disabled before

the machine is towed. Failure to release the parking

brake

and/or

disable

the

final

drives

before

the

machine is towed can damage the machine. Notify

Unit Maintenance to perform these procedures if the

machine must be towed.

Note: This information is not authorization for the operator

to maintain additional tools or to perform maintenance

tasks.

These towing instructions are for moving a disabled

machine a short distance, at low speed (no faster than

2 kph [1.2 mph]) to a convenient location for repair.

These instructions are for emergencies only. Always

haul a disabled machine if long distance moving is

required.

Shielding must be provided on the towing machine to

protect the operator if the tow line, or bar, should

break. The rear window screen on the DEUCE must

be down when the machine is towing or being towed.

Do not allow an operator on the machine being towed since

it is not possible to control the steering and braking.

Before towing, make sure the tow line, or bar, is in

good condition and has enough strength for the

towing situation involved. Use a towing line, or bar,

with a strength of at least 1.5 times the gross weight

of the towing machine for a disabled machine stuck in

the mud, or when towing on a grade.

Do not use a chain for pulling. A chain link may break,

causing possible injury. Use a wire rope cable with

loop or ring ends. An observer (in a safe position)

should stop the pulling procedure if the cable starts to break

or unravel. Stop pulling whenever the pulling machine

moves but the towed machine does not.

Keep the tow angle to a minimum. Do not exceed a

30-degree angle from the straight-ahead position.

Quick machine movement could overload the tow line,

or bar, and cause it to break. Gradual and smooth machine

movement works better.

Normally, the towing machine should be as large as

the disabled machine. Satisfy yourself that the towing

machine has enough brake capacity, weight and

power, to control both machines for the grade and distance

involved.

To provide sufficient control and braking when towing

a disabled machine down a hill, a larger towing

machine or additional machines connected to the front may

be required. This prevents it from rolling uncontrollably.

All different situational requirements cannot be given,

as minimal towing machine capacity is required on

smooth level surfaces, and increased capacity is

required on inclines or poor surface conditions.

Any towed machine, when loaded onto a trailer, must

be equipped with its own brake system which is

operable from the operator’s compartment.

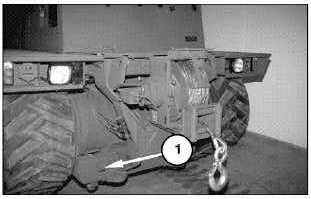

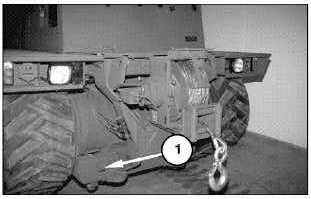

When towing the machine, use towing brackets (1) at the

rear of the machine, on both sides of the winch.