NOTE: If necessary, the blade can be collapsed to

reduce the total shipping width. Refer to

“Transportation Information, Preparation for Special

Shipping Width” in this manual.

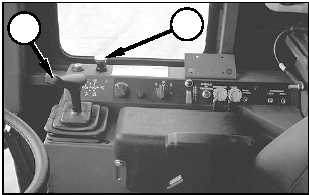

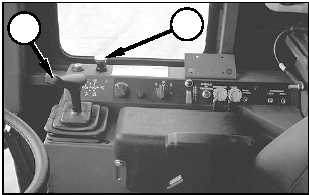

12. Move blade control lever (1) towards the front of

the machine, and lower the blade until the blade

contacts the floor of the aircraft.

13. Stop the engine. Refer to “Machine Parking,

Engine Stopping,” and “Machine Parking, Leaving

the Machine” in this section for procedures for

stopping the engine and leaving the machine.

14. Block the front and rear of each drive belt.

15. Secure the machine to the floor of the aircraft by

using the six tie-down locations on each side of

the machine. Refer to “Transportation Information,

Tie Down” in this section for the tie-down

locations.

Drive Off

NOTICE

If the cooling system was drained for transport, refill

the system before starting the engine. Operating the

machine without coolant will damage the engine.

1. Start the engine.

NOTE: For operating instructions, refer to “Before

Starting the Engine,” “Engine Starting,” “After Starting

Engine,” and “Machine Parking” in this section.

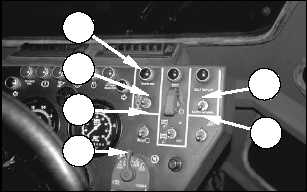

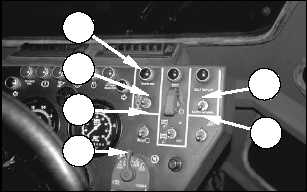

2. Ensure that blackout light switch (6) is in the STOP

LIGHT or SERVICE DRIVE position.

3. Move blade control lever (1) towards the rear of the

machine to fully raise the blade.

4. Move the self-deploy/earthmoving switch into

SELF-DEPLOY position (7).

5. Drive the machine off the aircraft.

NOTICE

Do not operate the machine at speeds greater than 3

kph (2 mph) in the kneeled position.

6. When the machine is in an open location, depress

service brake pedal (12), and move transmission

control lever (11) to NEUTRAL.

7. Pull knob (2) up to engage the parking brake before

releasing service brake pedal (12).

8. Move the kneeling switch to LOWER (4). Hold the

kneeling switch in the LOWER position for several

seconds to release any force on the kneeling lock

pins caused by natural leakage inside the kneeling

cylinders.

9. Remove the kneeling lock pins on both sides of the

machine and return the pins to the electrical panel

and BII compartment for storage.

10. Move the kneeling switch to RAISE (5). Hold the

kneeling switch in the RAISE position until the

machine is fully raised.

Preparation for Special Shipping Width

The shipping width of the machine can be reduced to

2591 mm (102 in). Notify Unit Maintenance personnel

to prepare the machine for the special shipping width.

Refer to Appendix E for Unit Level transportation

procedure. U.S. Army Operators are not authorized to

perform the procedures in Appendix E.

1

2

7

8

3

4

5

6

84

Operation Section

Transportation Information

TM5-2430-200-10