You must first read and understand the warnings

and instructions contained in this manual before

performing any operation or maintenance

procedures.

Walk-Around Inspection

When checking the specific components or areas on

the machine, be alert for oil or fuel leaks, loose or

missing fasteners, filler caps, or identification/safety

plates, and cracked or bent components. Have Unit

Maintenance make any needed repairs before

operating the machine.

NOTE: Army operators should perform the Operator’s

Preventive Maintenance Checks and Services

(OPMCS) before operating the machine. Refer to

Appendix A in this manual for the check list.

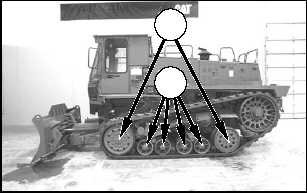

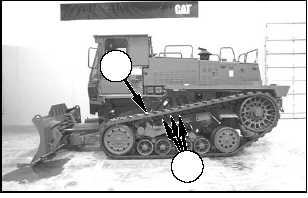

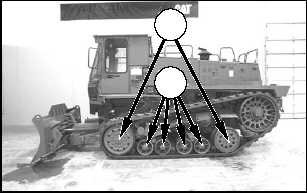

Undercarriage

Clean away any dirt and debris that has accumulated

in the undercarriage area, then inspect the following

components.

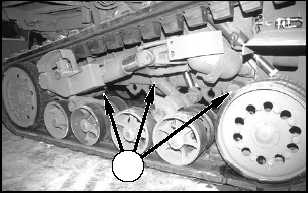

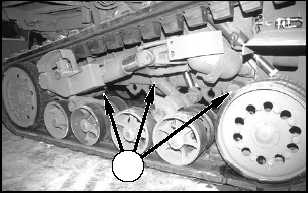

Drive Belts

Have Unit Maintenance replace belts (1) if any of the

following conditions are met:

• More than two guide blocks (2) in a row are missing.

• More than 12 guide blocks (2) (one quarter of the

total number) are missing.

• Belt (1), including internal cables, is severed more

than 40 percent of the width of the track, at any

location.

Midrollers and Idlers

Have Unit Maintenance repair or replace idler (3) or

midroller (4) if the following conditions are met:

• Oil is leaking enough to form drops.

• More than 50 percent of the rubber is missing from

any midroller (4) or more than 25 percent of the

rubber is missing from any idler (3).

• There are loose or missing bolts.

Swing Arms

Check swing arm pivot joints (5) for loose or missing

bolts.

5

3

4

1

2

Every 10 Service Hours or Daily

112

Maintenance Section

Every 10 Service Hours or Daily

TM5-2430-200-10