TM5-2430-200-10

73

Operation Section

Operating Techniques

Operating Techniques

Alert ground support personnel to stay a minimum of

50 feet from the DEUCE during dozing operations.

Failure to comply may result in injury or death from

flying rocks and debris.

NOTE: The illustrations in this section are not specific to

the DEUCE. However, the techniques described are valid

operating techniques for the DEUCE.

Bulldozing

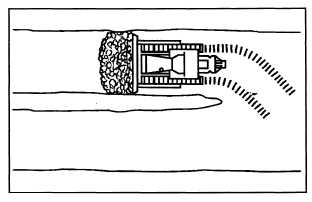

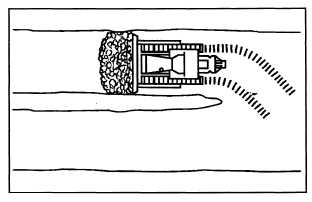

Straight Dozing

For the best performance during straight dozing, a level

cut should be maintained. After the bulldozer blade is

filled, the load should be carried to the landfill.

Do not lug or stall the machine.

Do not allow the drive belt to spin excessively.

If the machine must be turned under load, the

bulldozer tilt cylinders, not the steering wheel, should

be used to steer the machine.

During leveling work, a full bulldozer blade can be

managed more effectively than a partially loaded

blade.

Slot Dozing

NOTICE

During slot dozing, side wall cave in may occur,

potentially causing damage to the drive belt and

suspension.

When material is trapped in a slot, larger loads can be

carried in front of the bulldozer blade.

Once depth of slot exceeds blade height production will

decrease when using this method. Decrease is due to

excess spoil falling back over blade.

Moderate breaking and reverse gear one (R-1) must

be used when backing down any slope. Failure to do

so could result in death or injury.

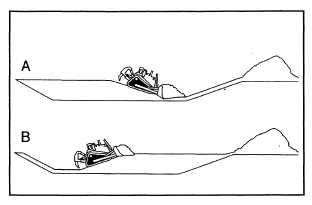

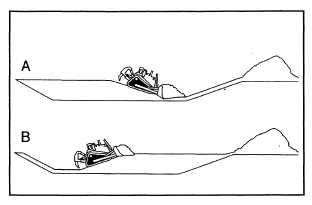

Start at the dump end, and operate rearward. This is

shown in Figure (A). This technique permits loading

downhill, and the carrying of a load on a level surface.

When working from the rear of the slot to the dump

end, the previous technique is more efficient. This is

shown in Figure (B). Uphill loading does not utilize the

slot. This is shown in Figure (B). Level dozing through

the entire slot is inefficient, due to the longer distance

of the push.

When parallel slots are dug, the center should be

removed from the rear. This procedure permits the

operator to maintain a slot until the center is removed.

The center should be maintained at a minimum width.

The maximum width should be approximately one-

third of the bulldozer blade.