Keep personnel clear of the blade while the blade

is raised. The blade could fall, resulting in injury

or death.

7. Move the self-deploy/earthmoving switch to SELF-

DEPLOY position (15).

NOTE: The machine must be in the SELF-DEPLOY

mode to unlock the suspension. Refer to “Machine

Operation, Self-Deploy Mode” in this section for the

procedure to place the machine in the SELF-DEPLOY

mode.

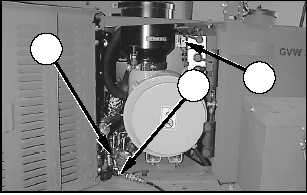

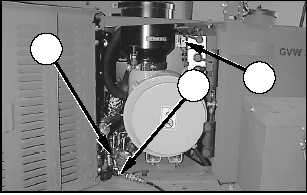

8. With the engine operating at low idle, hold auxiliary

charge switch (16) up to direct hydraulic oil into the

recoil cylinder.

9. Watch the pressure reading on the pressure gauge

on gauge assembly (9).

10. Release auxiliary charge switch (16) and close ball

valve (5) (turn the valve knob perpendicular to the

valve body) when the pressure reading on the

pressure gauge reaches 15 170 kPa (2200 psi).

NOTICE

Overtightening the drive belt will cause accelerated

wear of undercarriage components and decreased

machine performance.

11. Turn nut (2) three-quarters of a turn

counterclockwise (this locks the valve). Open ball

valve (5) (turn the valve knob in line with the valve

body).

12. Remove coupling (6) from fitting (12).

13. Repeat Steps 4 and 8 through 11 for the other

drive belt, if necessary.

14. Remove coupling (7) from pressure tap (11) on the

multifunction valve.

15. Turn nut (2) counterclockwise, until the nut stops

rotating (an additional three-quarters of a turn may

be required). Remove coupling (6) from fitting (12).

16. Disconnect coupling (8) of the gauge group from

coupling (3) of the charge hose. Disconnect

coupling (10) of the gauge group from coupling (4)

of the charge hose. Connect coupling (3) to

coupling (4). Return the charge hose and gauge

group to the BII compartment for storage.

17. Deliver the machine to Unit Maintenance as soon

as possible to recharge the suspension.

5

9

16

15

WARNING

!

68

Operation Section

Machine Operation

TM5-2430-200-10