66

TM5-2430-200-10

Operation Section

Machine Operation

Back Rippers

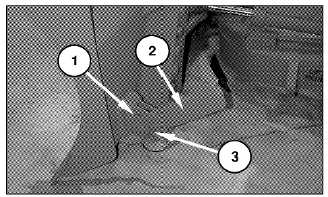

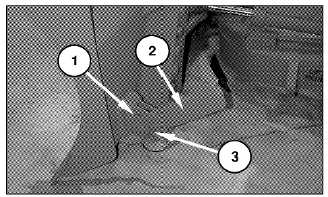

To lower the back rippers for use, remove pin (3) while

holding ripper (2). Allow the ripper to rest on the

ground and install the pin in hole (1).

To raise the back rippers for storage, remove pin (3)

from hole (1). Raise ripper (2) and secure it in place with the

pin, as shown.

Emergency Suspension Charging and

Emergency Drive Belt Tension

Procedure

The hydraulic system operates at high pressure. Wear

eye and face protection, gloves and protective clothing

when performing this procedure. Failure to comply may

result in severe injury or death.

NOTICE

This procedure is for emergency field use, to mobilize the

machine if either of the drive belts become loose. If this

procedure is performed for any reason, deliver the machine

to Unit Maintenance to have the suspension properly

charged before returning the machine to normal service. Do

not overcharge the cylinders.

Suspension Hydraulic Charge Specifications

Description

Minimum Charge

With Machine On

Ground in kPa (psi)

Middle Suspension Cylinders

8276 ±690 (1200 ± 100)

Bogie Cylinders

11790 ±690 (1710 ± 100)

Recoil Cylinders

15170 ±690 (2200 ± 100)

NOTE: The same procedure can be applied to either side of

the machine.

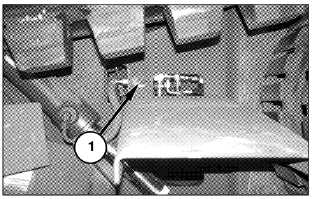

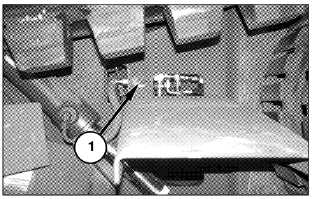

1. Open suspension manual lock valve (1) by rotating

the valve clockwise.

NOTE: The emergency drive belt tension procedure

will not work if the suspension is locked.

NOTE: Thoroughly clean the couplings of all hoses

used in this procedure before connecting the coupling

to any port on the machine.