Accumulator and connecting lines may be

pressurized.

Read and follow the maintenance manual and the

instructions below before working on the

accumulator and connecting lines.

Failure to follow the maintenance manual or the

instructions can cause rapid discharging of gas

or hydraulic fluids which can result in injury or

death.

1. Slowly bleed all hydraulic pressure off the

hydraulic side of the accumulators by using the

hydraulic disconnects.

2. Slowly discharge all gas pressure by opening

gas valve at one end of the accumulator until gas

begins to escape. Wait until all gas pressure is

relieved

before

proceeding

with

next

maintenance procedure.

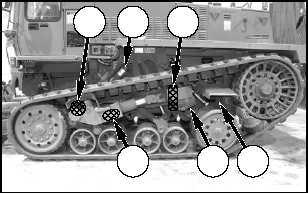

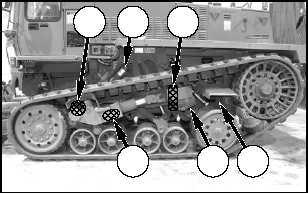

(13) Brake accumulator, beneath cab. (14) Front cylinder

accumulator, each side of machine. (15) Middle cylinder

accumulator, each side of machine. (16) Bogie cylinder

accumulator, each side of machine. (17) Recoil accumulator,

each side of machine. (18) Kneeling accumulator, each side of

machine.

Accumulator warning labels are attached to each

accumulator on the machine.

General Hazard Information

Attach a Do Not Operate warning tag to the start

switch or controls before servicing or repairing the

machine. This tag is available from TACOM.

Know the width of your attachments so that proper

clearance can be maintained when operating near

fences, boundary obstacles, etc.

Wear a hard hat, protective glasses, and other

protective equipment as required by job conditions.

Wear eye and face protection when working with

hydraulic or air lines.

Do not wear loose clothing or jewelry that can catch

on the controls, or other parts of the machine.

Make certain that all protective guards and covers are

secured in place on the machine.

Keep the machine, especially the deck, walkways and

steps, free of foreign material; such as debris, oil, tools

and other items which are not part of the machine.

Secure all loose items such as tools and other items

which are not part of the machine.

Know the appropriate work site hand signals and who

gives them. Accept signals from one person only.

Do not smoke when servicing air conditioners or

wherever refrigerant gasses may be present. Inhaling

air-conditioner refrigerant gas through a lit cigarette or

other smoking method or inhaling fumes released from

a flame contacting air-conditioner refrigerant gas can

cause bodily harm or death.

Never put maintenance fluids into glass containers.

Drain all liquids into a suitable container. Dispose of all

liquids according to local regulations.

Use all cleaning solutions with care.

Report all needed repairs.

Do not allow unauthorized personnel on the machine.

Do not operate the engine coolant heater while

refueling the machine. Do not place any combustible

or heat sensitive material within 50.8 mm (2 in) of the

heater’s exhaust system. Routinely inspect the fuel

delivery system for leaks. Repair all leaks before

operating the heater. Operation of the heater

produces harmful vapors which represent an

asphyxiation hazard. To guard against asphyxiation:

do not operate the heater in an enclosed space;

ensure that no exhaust fumes enter the operator’s

compartment. Exhaust components can be extremely

hot. Do not touch the exhaust components until the

parts are cool.

13

14

15

16

17

18

WARNING

!

9

Safety Section

Safety

TM5-2430-200-10