TM 5-5420-226-20-1

INTRODUCTION - Continued

When checking fluid levels, vehicle must be on level surface.

Oil filters shall be serviced/cleaned/changed when they are known to be contaminated or

clogged, service is recommended by AOAP, or hard time service is required.

Dispose of used lubricants in accordance with local Standing Operating Procedures (SOP).

For arctic operation, see FM 9-207.

For desert operation, see FM 90-3.

Clean all grease fittings before attaching grease gun.

When using grease gun, operate until grease appears around seals or out of relief valve and

check escaping grease for contamination. If contamination is found, notify support maintenance.

If no other treatment is directed, paint or clean and coat unprotected metal surfaces with

cleaner, lubricant, preservative (CLP).

Clean around filler necks/drain plugs/openings before servicing to keep dirt from entering

system.

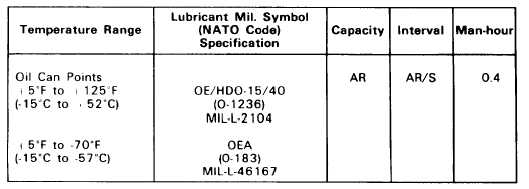

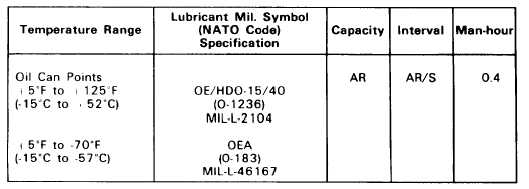

Lubricate oil can points as they become accessible while performing PMCS procedures. Use the

applicable lubricant identified and lubricate the following items as a part of PMCS:

Headlight removal nuts

Grille door hinges

Fender stowage box latches and hinges

Control rod clevises

Towing hooks (hinge pin)

Ammunition box latches

Brake linkage

Driver’s and commander’s

Transmission support guide

seats moving parts

rails and rollers

Hatch locks and hinges

Driver’s escape hatch late

Universal joints

model (clean and coat pins, plungers,

Driver’s night viewer hatch

and all unpainted surfaces)

door pivot pin and latch

Oil Can Points Lubricants

For arctic operation, see FM 9-207

not lubricate the following items:

Starter solenoid

Air cleaner blower motor

Hydraulic powerpack electric

motor

Heater motor

Gas particulate fan motor

Tracks

Tachometer drive adapter

Ventilator blower motor

Any item not pointed out.

3-10

Change 6