TM 5-5420-226-20-1

P r e v e n t i v e M a i n t e n a n c e C h e c k s a n d S e r v i c e s f o r M 4 8 A 5 A V L B H u l l -

Item

No.

23

Interval

Location

Item to

Check/Service

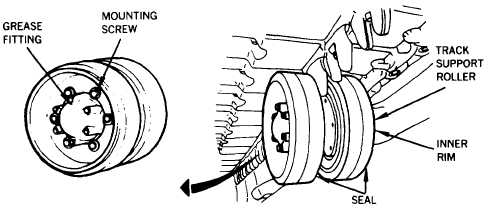

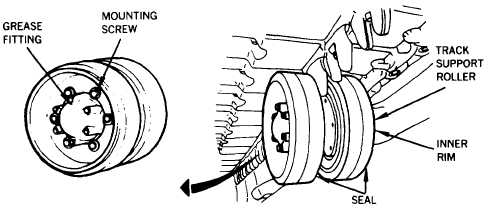

Track Support

Rollers (Left and

Right Sides)

C o n t i n u e d

Procedure

Check track support roller seals and

bearings by inspecting inboard side

of track support rollers for grease

spattering along inner rim.

If there is grease spattering on inner

rim, clean all lubricant from behind

the roller, seal, and along roller in-

ner rim, check for space at bottom

side of seal indicating worn or dam-

aged bearings.

If lubricant spattering is found,

track support roller seal is defective.

Replace defective seal (page 14-36).

Check if support roller mounting

screws and grease

aged or missing.

fitting are dam-

Not Fully Mission

Capable if:

Any class III

leak.

Any worn or de-

fective bearings.

3-32

Change 6